170mm diamond antique brush fickert model 5 steps to create antique finish on granite, quartz slabs

Product Video

escription:

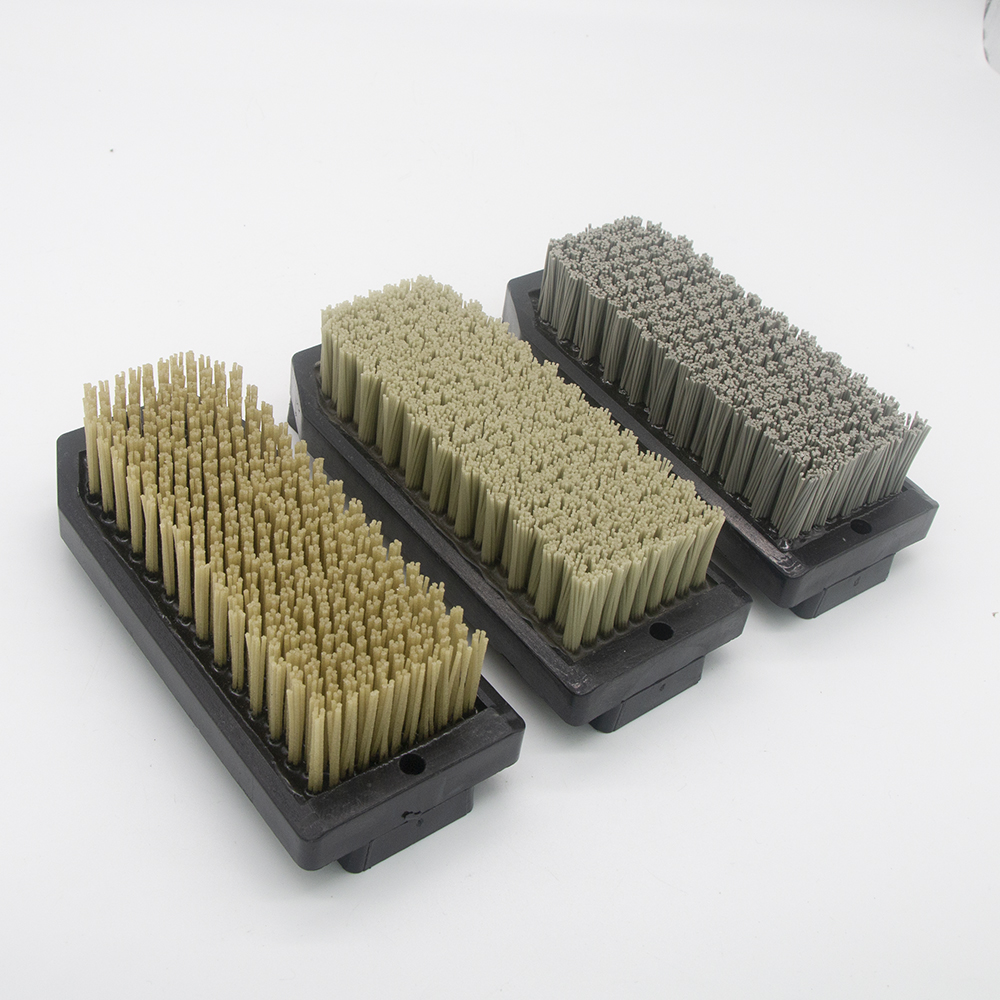

Diamond fickert brushes are usually made of 20% diamond grain and nylon PA612 and other minerals,which is the most sharpest and strongest consumables for grinding granite, quartz, ceramic tiles to achieve antique or leather finish.

The bended edge of plastic mounting is designed based on the polishing head swing principle, it can prevent the plastic mounting breaking the slabs while the wires are almost running out, meanwhile the wires can be used completely, the residue is usually 2-3mm.

Product introduction

The highlight of these diamond antique brushes is the diamond wires are evenly distributed in plastic mounting, it can bear more pressure and grind the stone surface completely everywhere, the finish effect is better than normal brushes.

Fickert brushes are usually attached to the polishing head (fickert type) of automatic machine that rotates to provide the necessary friction and pressure for polishing. It can remove the soft grains and scratches of surface, creating a beautiful leather finish on stone surfaces.

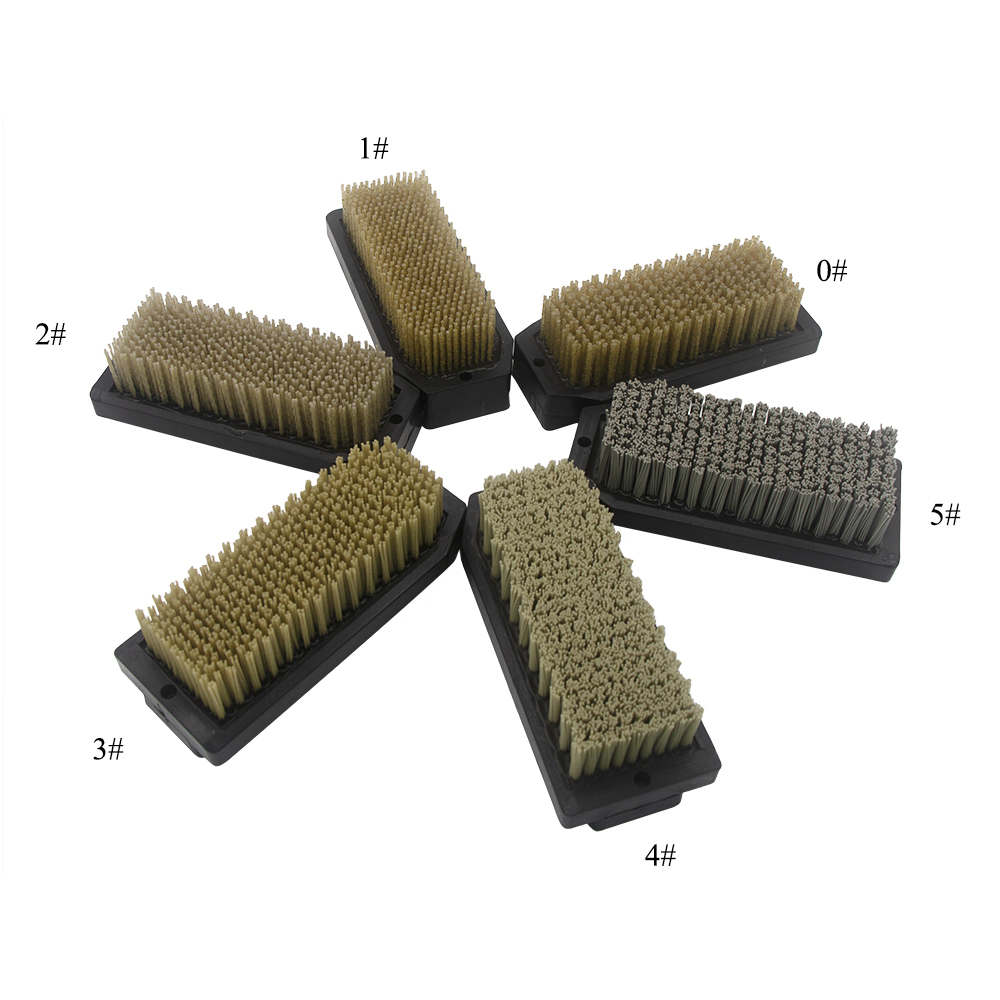

Normally the grit is 24# 36# 46# 60# 80# 120# 180# 240# 320# 400# 600# 800# 1000# 1200#, but we sifted and simplified the grit to be 1# 2# 3# 4# 5# which shortened the process but create better surface effect.

Application

Sequence of abrasive brushes making leather surface on artificial quartz, granite, ceramic tiles

(1)Diamond brush 1# 2# 3# 4# 5# to achieve antique finish.

Parameter & Feature

Length 158mm * width 67mm * height 53mm

Wires length: 30mm

Main material: 20% diamond grain + PA612

Material of base: plastic

Fixing type: adhesive (glued fixing)

Feature

This kind of diamond antique brushes are a revolution and have better property. Sharp and durable diamond filaments which are distributed evenly on brushes, it can polish every corner of the stone surface and obtain better antique finishing.

Leather finishing is typically done on materials such as granite, marble, and quartz. It can be achieved through a process of grinding the stone surface by using diamond brushes and silicon brushes.