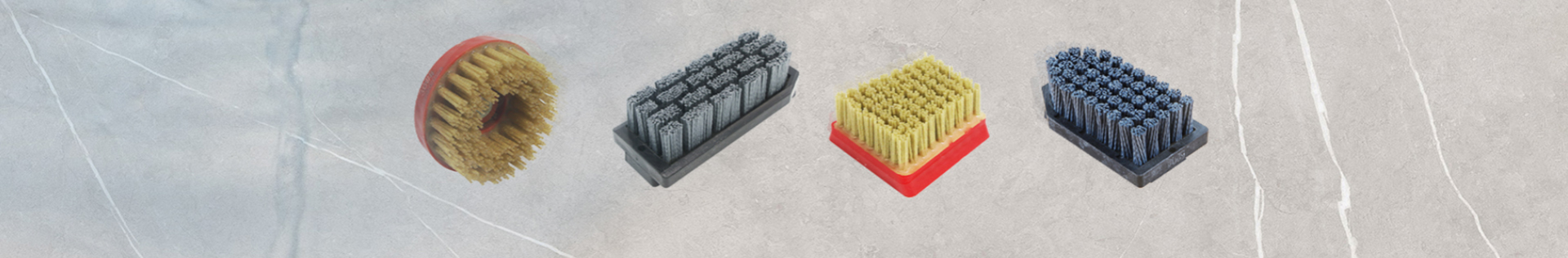

L140mm Mat Rubber Brush Airflex texturing Brush Filiflex antique brush

Product Video

Product Introduction

The Filiflex and Airflex brushes work on the material digging the softest parts, rounding up and smoothing the hardest ones. For an irregular but at the same time harmoniously wavy and natural-looking surface. Pleasantly irregular to the touch and with a particularly intense color, the final finish can be matte or shiny, more or less irregular, according to the sequence used.

The grit of Filiflex brush is from 180# - 3000#. Made with many narrow bristles, the Filiflex brush removes material more aggressively and cuts deeper to create a nice antique look. The Airflex brush, which starts at 120 grit adds color and forms a beautiful soft antique look. Grits used to create a typical antique finish: Start with Filiflex 36, 46, and 60 grit. Then finish with Airflex 120, 220, and 300 grit. Higher grits are available to create shiny surface.

rushes remove softer materials in the stone to create a beautiful texture.

Give the stone exceptional depth.

Mainly used to create a antique finish.

Airflex texturing Brush can be used on continuous polishing machines that for fabricating different kinds of stone like ceramic tile and artificial quartz to create matt and soft light finish.

Airflex brushes remove the “softer” material in the stone to create a beautiful texture while enhancing the natural color in the stone.

Application

Airflex texturing Brush is mainly applied to polishing ceramic tile and quartz slabs, reach to matt antique finish.

Parameter & Feature

• Size: L142*H34*W65mm

• Material: diamond particles+ silicon carbide particles + resin bond

• Regular grit: 180# 240# 320# 400# 600# 800# 1000# 1200# 2000# 3000# 6000#

• Application: for making matt or soft light finish on ceramic tile or artificial quartz stone, the texture of stone will be more clearer after applying these abrasive tools.

Feature

Airflex antiquing brushes are top quality and for processing luxury stones,it help you easy to get the beautiful antiqued, leather finish on the stone surface. Use at low speeds with some water and very little pressure.

FAQs

Normally there’s no quantity limited, but if for samples testing, we do suggest you take the enough quantity so you can obtain the desired effect.

For examples, our production capacity for abrasive brushes is 8000 pieces per day. If goods are in stock, we will send out within 1-2 days, if out of stock, production time might be 5-7 days, because the new orders have to wait in line, but we will try our best to deliver ASAP.

L140mm Fickert brush: 24 pieces / carton, G.W.: 6.5KG/carton(30x29x18cm)

L170mm Fickert brush: 24 pieces / carton, G.W.: 7.5KG/carton(34.5x29x17.4cm)

Frankfurt brush: 36 pieces / carton, G.W.: 9.5KG/carton(43x28.5x16cm)

Non-woven nylon fiber:

140mm is 36 pieces / carton,G.W.: 5.5KG/carton (30x29x18cm);

170mm is 24 pieces / carton,G.W.: 4.5KG/carton (30x29x18cm);

Terrazzo frankfurt magnesite oxide abrasive : 36 pieces / carton, G.W.: 22kgs / carton (40×28×16.5cm)

Marble frankfurt magnesite oxide abrasive : 36 pieces / carton, G.W.: 19kgs / carton (39×28×16.5cm)

Terrazzo resin bond frankfurt abrasive : 36 pieces / carton, G.W.: 18kgs / carton (40×28×16.5cm)

Marble resin bond frankfurt abrasive : 36 pieces / carton, G.W.: 16kgs / carton (39×28×16.5cm)

Cleaner 01# abrasive : 36 pieces / carton, G.W.: 16kgs / carton (39×28×16.5cm)

5-extra / 10-extra oxalic acid frankfurt abrasive: 36 pieces / carton, G.W.: 22. 5kgs / carton (43×28×16cm)

L140 Lux fickert abrasive: 24 pieces / carton, G.W.: 19kgs / carton ( 41×27×14. 5cm)

L140mm Fickert magnesium abrasive: 24pieces / carton ,G.W.: 20kgs / carton

L170mm Fickert magnesium abrasive: 18 pieces / carton ,G.W.: 19.5kgs / carton

Round brush / abrasive will depend on the quantity , so please confirm with our service.

We accept T/T, Western Union, L/C (30% down payment) against original B/L.

These abrasive tools are consumable commodities, normally we support refund within 3 months if any defective issue(which normally won’t happen). Please make sure keep the abrasive in dry and cool circumstance, in theory, the validity is 2-3 years. We suggest that clients purchase enough consumption for three months of production, rather than stocking too much at one time.

Yes, we can customize the goods as per your drawing, but it will involve mould fee and require bulk quantity. Mould time will takes 30-40 days normally.