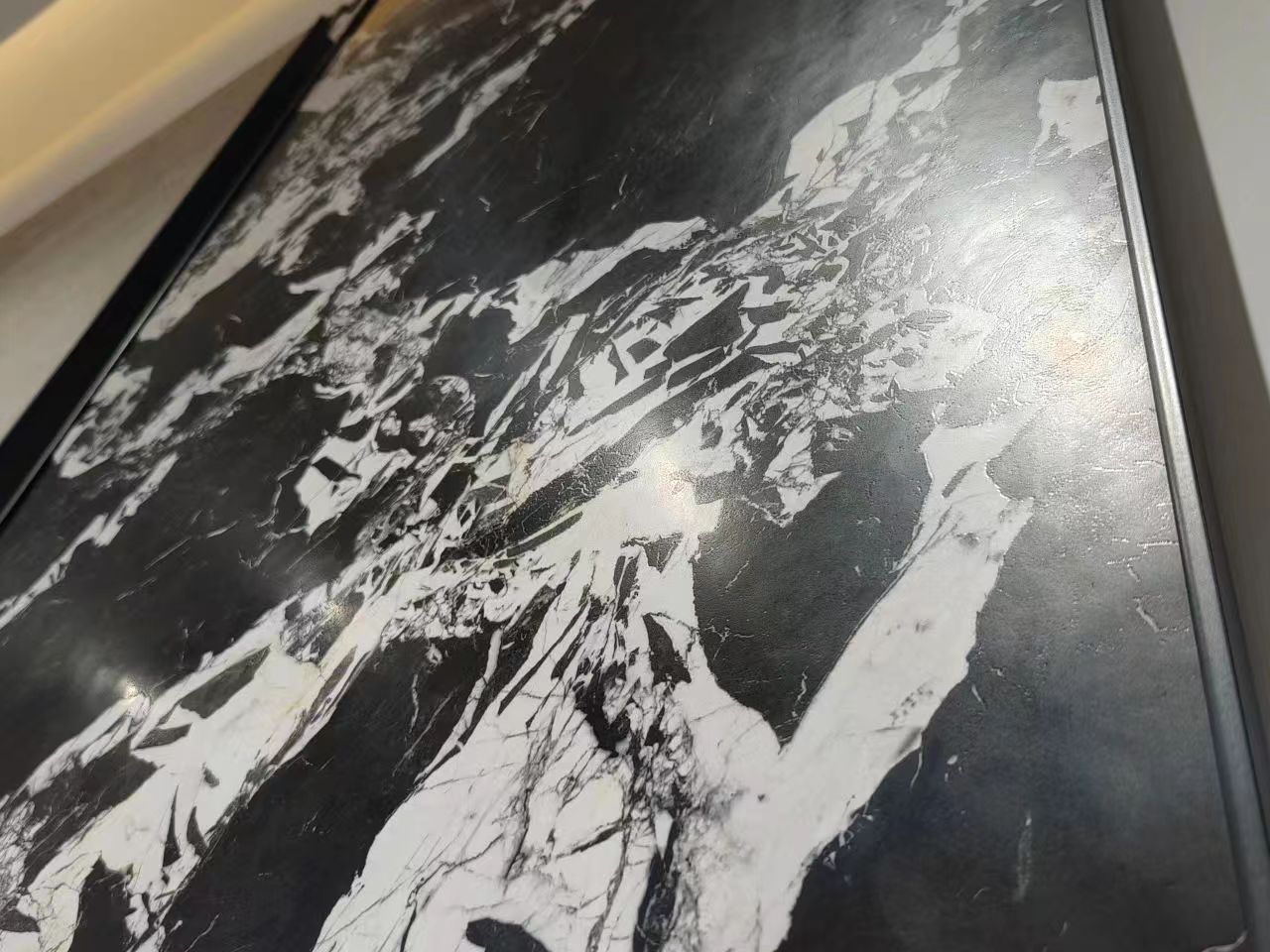

One unique surface has been popular these two years,especially in ceramic tile industry. It combines both antique and satin finishes, offering better anti-fouling ability and easy cleaning.

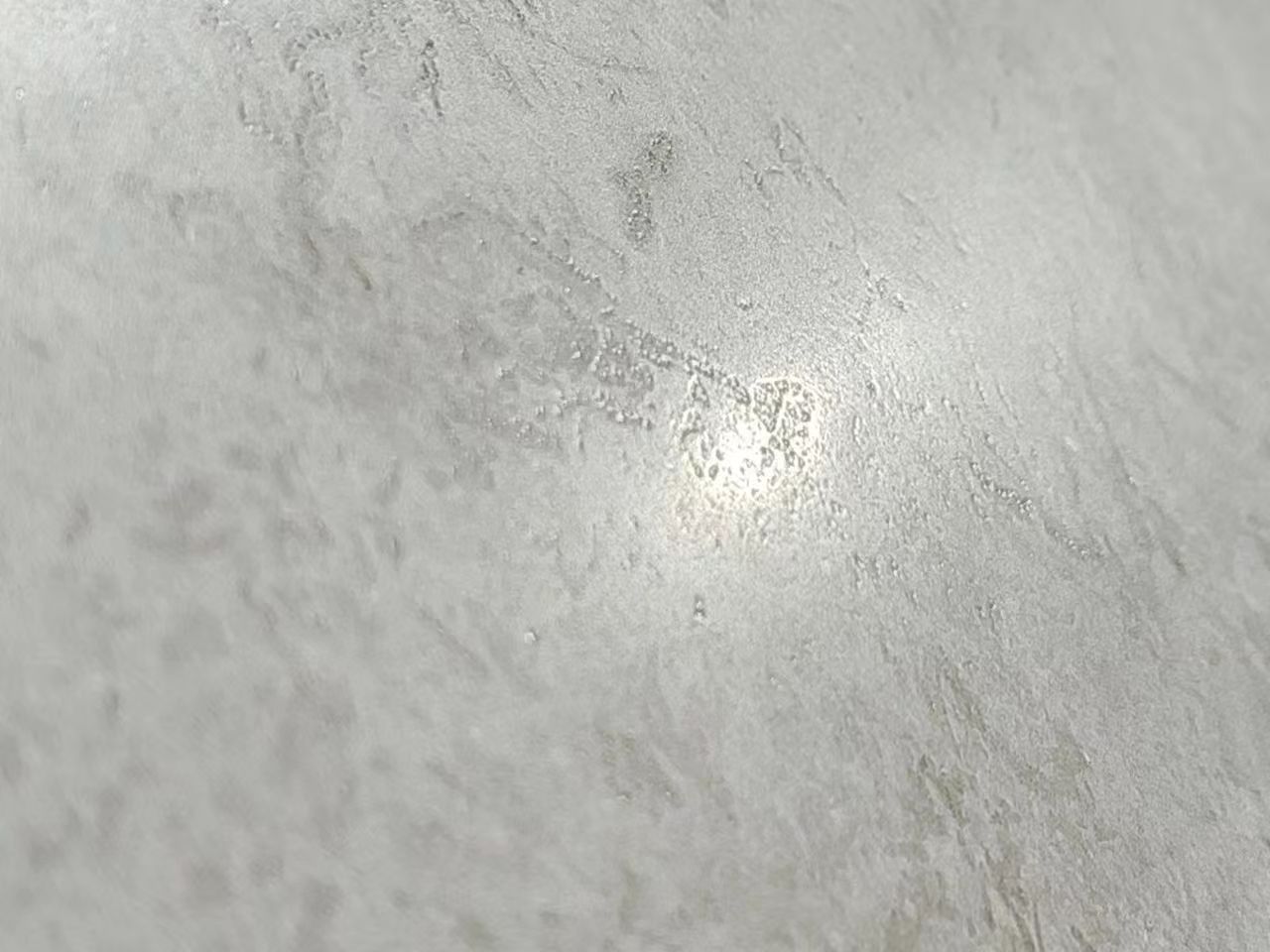

This unique surface resembles the stone laid in European castles and churches, providing an aged appearance that evokes a sense of history. It perfectly captures the essence of natural stone, restoring the texture and light reflection of marble. The surface has an antique effect, both silky smooth like satin and slightly convex with a three-dimensional touch. Additionally, it offers a soft light and an old-time feel, highlighting rich histories and stories.

Some friends might be curious about how to achieve this finish and which abrasive tools are used.

For examples, in ceramic indutry, the process is divided into three steps: creating an antique surface, smoothing the surface, and applying anti-fouling chemicals. The relevant abrasive tools include abrasive brushes, sponge diamond polishing pads, and nano liquids.

1. Diamond antique brush or silicon antique brush: Using the antique brush grind the ceramic tiles (stone) surface, eroding it with aggressive abrasive wires, removing soft grains to create a concave surface while leaving hard grains smooth after polishing.

2. Smoothing and enhancing gloss: To achieve a satin surface, use sponge diamond polishing pads with grits of 120#, 180#, 240#, 320#, and 400#. These pads can increase the glossiness to 15-35 degrees.

3. Applying chemical liquids: The final step involves covering the surface with chemical liquids to prevent pollution from tea stains, coffee, oil, etc. This step also slightly increases glossiness and covers micro-scratches that are not visible to the naked eye.

If you want to know more details, please feel free to contact us at any time.

Post time: Jul-16-2024