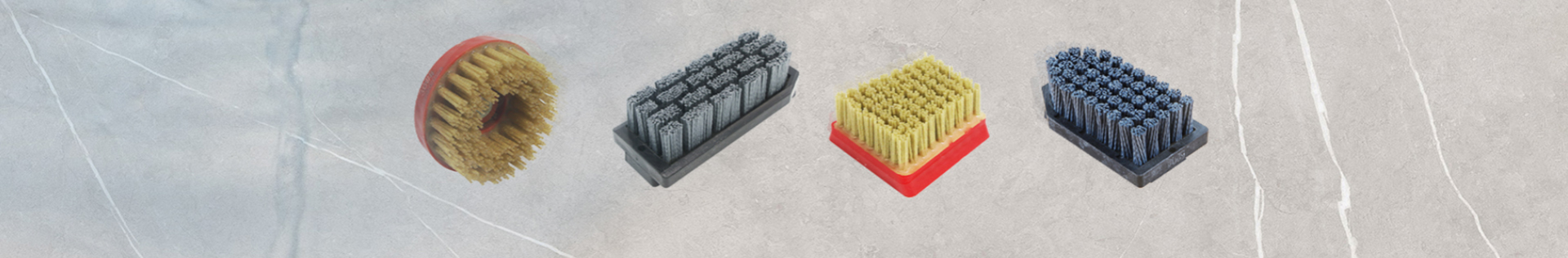

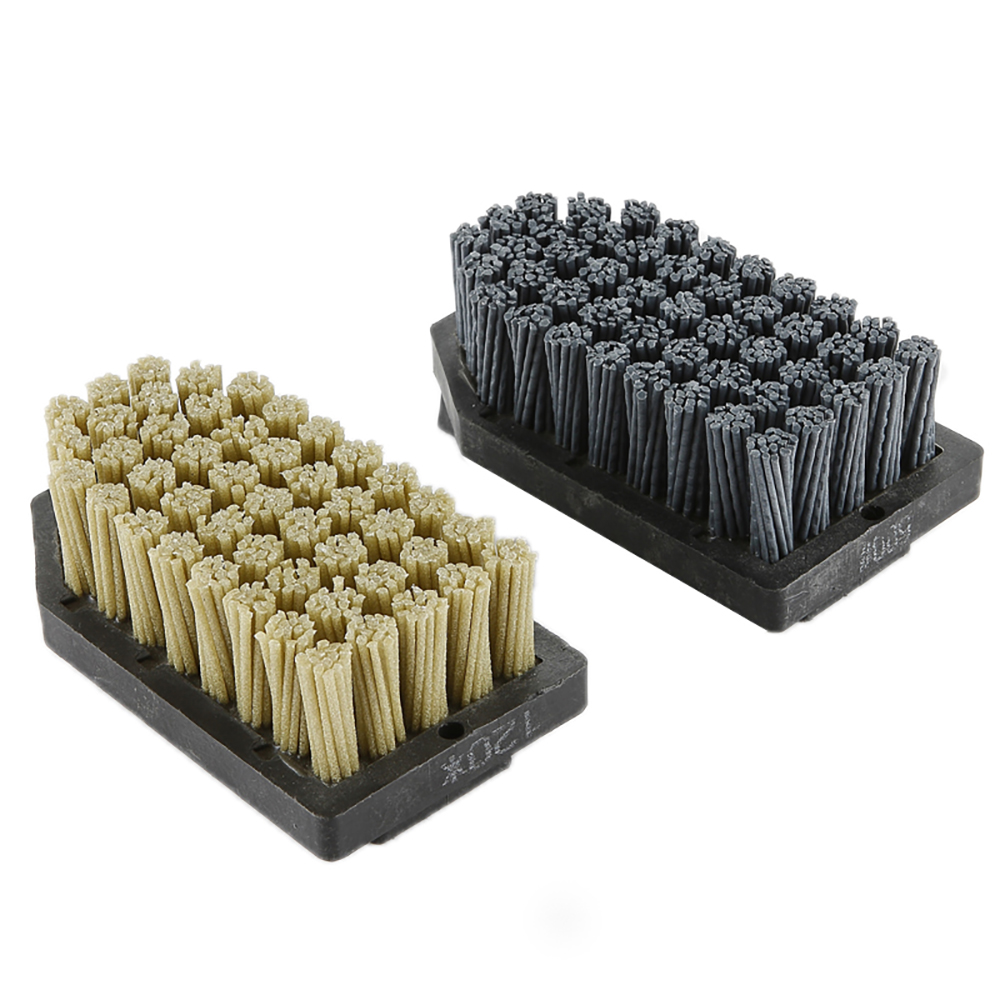

As we all know that abrasive brushes are dedicated tools for the stone polishing process. These brushes are usually made of abrasive materials such as diamond bristles or silicon carbide bristles, which help effectively remove scratches, smooth surfaces and bring out the natural luster of the stone. These brushes are commonly used in applications such as marble, granite, and quartz countertop fabrication, floor polishing, and stone surface restoration.

The service life of abrasive brushes can be affected by several factors. Some of the main factors that affect the life of abrasive brushes during operation include:

1.Material Hardness: The hardness of the stone being polished can significantly affect the service life of the abrasive brush. Hard stones such as granite or quartz will cause more wear and tear on your brushes than soft stones such as marble.

2.Applied pressure: The amount of pressure applied when using an abrasive brush will affect its lifespan. Excessive pressure will cause the bristles to wear out faster, reducing the lifespan.

3.Abrasiveness of the stone: A stone with a higher abrasiveness will cause the bristles on your brush to wear down faster.

4.Speed and rotation: The speed and rotation at which an abrasive brush is used will also affect its lifespan. Higher speeds or excessive rotation will accelerate bristle wear.

5.Cleaning and Maintenance: Proper cleaning and maintenance of abrasive brushes is critical to their longevity. Regularly cleaning your brushes and removing debris and grout buildup will help maintain their effectiveness and prolong their life.

6.Quality of brushes: The quality of abrasive brushes also affects their service life. High-quality brushes made from durable materials and superior manufacturing techniques tend to last longer than lower-quality brushes. It is worth noting that the service life of abrasive brushes may vary depending on the specific conditions of use and the quality of the brush. Regular inspection and replacement of worn brushes will help maintain optimum polishing performance.

7.Workers’ skills and experience will also affect the service life of abrasive brushes.

Proper Technique: A skilled worker with experience using abrasive brushes is more likely to use correct technique. This includes applying the right amount of pressure, maintaining a consistent speed and rotation, and using the correct angle. Proper technique can minimize excessive wear on your brushes, thus extending their life.

There might be other factors which also affect the lifespan of abrasive brushes that we omitted, please share with us, thanks for your attention.

Elaine: +86-13336414847(Whatsapp / Wechat),email:expert01@huirui-c.com

Alice: +86-13336448141(Whatsapp / Wechat),email:expert02@huirui-c.com

We’ll try our best to assist you and meet your requirement.

Please note: The contact information provided is for media inquiries and is intended for journalists or individuals seeking further information about the company.

Post time: Aug-18-2023