Resin Bond Synthetic Frankfurt Abrasive Block for Grinding Marble, Travertine, Limestone, Terrazzo 400# 600# 800# 1000# 1200#

Product Video

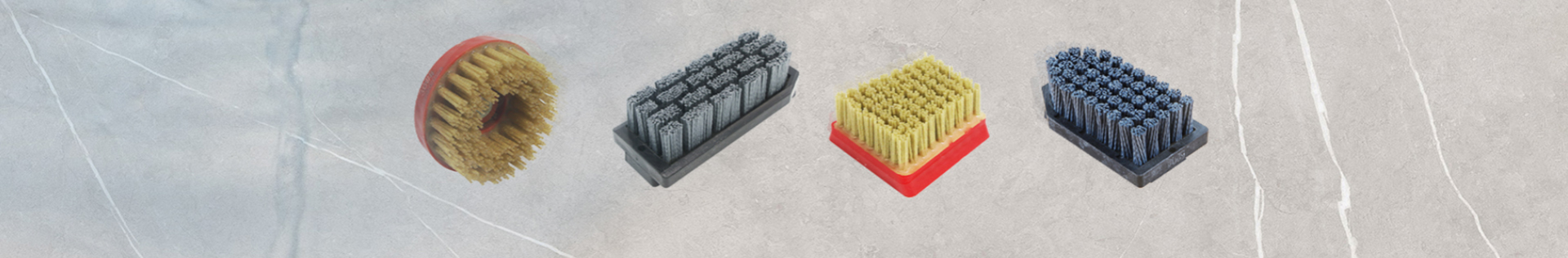

Description:

Resin bond frankfurt abrasive are usually used to grind marble / limestone / travertine / terrazzo slabs, usually installed on continuous automatic polishing line.

Grit: 400# 600# 800# 1000# 1200#

Grit 400# abrasive are made with better sharpness which plays an important role in shinning the marble surface. A good quality 400# will save more abrasive from 600# - 1200# and help get better polishing quality.

Product introduction

Main materials are green silicon carbide compound abrasive, its raw materials are firstly cold pressed and then cook at oven at certain temperature and time for best materials bonding and chemical reactions.

If used correctly, the resin bond frankfurt abrasive block can produce a high-gloss finish on marble surface. The abrasives are also effective in removing scratches, stains, and other blemishes, restoring the natural beauty of the stone.

Composition: rough grinding (magnesite abrasive 24# - 320#) + Medium / Fine grinding (resin bond frankfurt abrasive 400# 600# 800# 1000# 1200#) + precision polishing (5-extra / 10-extra oxalic acid abrasive)

Grit: 400# 600# 800# 1000# 1200#

Application

Resin bond frankfurt abrasive block from 400# to 1200# starts to get marble shinned with certain glossy before final polishing with 5-extra / 10-extra abrasive to process the marble surface to be mirror polished finishing.

Applicable machine: automatic polishing line of marble, travertine, limestone and terrazzo.

Parameter

Thickness: 50mm

Grit: 400# 600# 800# 1000# 1200#

Package: 36 pieces /carton

Feature

Resin bond frankfurt abrasive can be applied to grind all kinds to marble slabs, it has high grinding efficiency, good self-sharpening, goods wear resistance, fast glazing, high gloss,etc.

We suggest storing the resin bond frankfurt abrasive in dry and cool place, avoid dropping or hitting the tool, and do not use excessive pressure during polishing.